The double-sided solar modules can be divided into P-type double-sided and N-type double-sided according to the different crystal silicon substrates. At present, the mass-produced double-sided solar cell structure is mainly composed of P-type PERC double-sided, N-PERT double-sided and HIT.

"This year will be the first year of rapid development of double-sided solar modules." Many industry experts have expressed this view. Bloomberg New Energy Finance previously expected that the double-sided solar cell module market will reach 3GW in 2018, mainly for the front-runner project. After the 531 New Deal, the leader project has become one of the main domestic demand markets in the second half of the year. Among them, the total number of medium and double-sided solar modules in the application leader is about 2.6GW, accounting for 52%; the technical leader three bases 6 In the standard section, there are 4 sections to declare the double-sided technology. Although the current shipments of double-sided solar modules are still small, it can be seen from the SNEC exhibition and the front-runner project that the layout of double-sided technology has become the starting point of photovoltaic enterprises, and the double-sided technology is rapidly developing.

P-type double-sided vs. N-type double-sided, which one is better?

The double-sided solar modules can be divided into P-type double-sided and N-type double-sided according to the different crystalline silicon substrates. Currently, the mass-produced double-sided solar cell structure is mainly composed of P-type PERC double-sided, N-PERT double-sided and HIT.

Comparison of natural advantages and disadvantages of materials

N-type double-sided has different natural advantages over the P-type PERC due to the different silicon substrates, including high lifetime of the minority, no light decay, good low light performance, good temperature coefficient, high tolerance to metal impurities, etc.

(1) The minority carrier lifetime is high. Metal impurities are one of the common impurities in semiconductors, while N-type substrates are highly resistant to impurities and have a higher tolerance to common metal impurities such as iron and copper, that is, in the case of the same metal impurity contamination, N-type. The minority carrier lifetime of silicon wafers is higher than that of P-type silicon wafers. The high lifetime of the minority carrier is ultimately beneficial to the external output current, and the converted light energy will be more under the same illumination conditions.

(2) No photoinduced attenuation. Conventional P-type batteries use boron-doped silicon substrates to form boron-oxygen pairs after initial illumination, and trap electrons in the substrate to form a recombination center, resulting in 3-4% power attenuation, even with hydrogen passivation and other technologies. The light fading is completely eliminated; while the N-type double sided is different from the PERC double sided, the substrate is doped with phosphorus, and there is no loss of boron and oxygen to form a recombination center, so that the solar cell has almost no photo-induced attenuation.

(3) Good low lightness. Compared with P-type single crystals, N-type single crystals have a more sensitive perception of weak light. In the morning, evening, cloudy or rainy weather, N-type single crystals can capture more light for photoelectric conversion, and the output is The amount of electricity will be more.

(4) The temperature coefficient is good. The temperature coefficient is the rate at which the physical properties of the material change with temperature. Compared to the P-type single crystal, the open circuit voltage, short-circuit current, and peak power of the N-type single crystal change relatively slowly with changes in ambient temperature. It has superior high temperature resistance and higher power output in continuous high temperature environments.

Double-sided gain advantage comparison

Compared with P-type PERC double-sided, high-double-sided coefficient (that is, the ratio of back-side electrical parameters to front-side electrical parameters under standard test conditions) becomes a major advantage of N-type double-sided market share, N-PERT, HIT double-sided The coefficient can be higher than 90%, IBC is about 80%, and the double-sided coefficient of PERC is lower. Although some companies claim that they can increase the double-sided coefficient to about 80%, in terms of general production technology, PERC double-sided The factor is about 65% to 75%. Taking N-type double-sided representation of Yingli as an example, the mass production of its “Panda” technology has made Yingli the first company in the world to successfully realize mass production of N-type double-sided batteries.

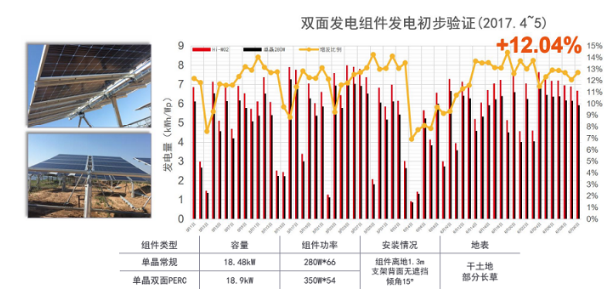

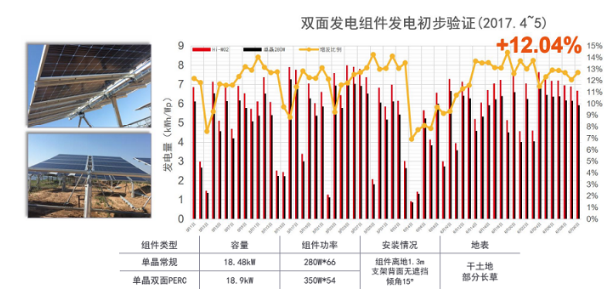

According to the Pucheng experimental power station data disclosed by Longji Leye, its 72 double-sided PERC solar modules (power 350W, front power) compared with 60 conventional polycrystalline solar modules (power 280W), 2017.05-2017.06 two months The average power generation gain is 12.04%.

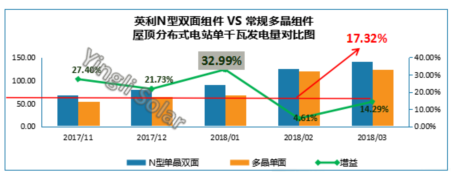

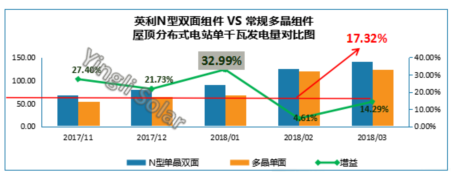

According to the data of Shanxi Liyang Distributed Power Station disclosed by Yingli, its 60 N-type double-sided solar modules (power 310W, double-sided power), compared with 60 conventional polycrystalline solar modules (power 280W), 2017.11-2018.03 The five-month monthly average power generation gain was 17.32%, the highest was 33%.

Yingli N-type double-sided is calculated according to the double-sided power. The component power already contains 11% of the back power, and the extra gain on the back side can still reach 17.32% on average, which proves that the aforementioned N-type double-sided coefficient is high and low light. Good performance, good temperature coefficient and no photoinduced attenuation.

In the same phase of the front-runner project, Yingli's 50MW “Panda” component has been the leader in power generation. The 2017 statistics show that the monthly power generation is up to 19. Compared with the conventional P-type single-sided polycrystalline power plant. 02%; It can be seen from the same period of operation in the same period from January to June in Datong City Development and Reform Commission that the power generation of Yingli “Panda” solar modules is as good as ever.

It is reported that in less than two years, Yingli has successively won the double-sided product certification of the three major institutions of Jianheng, UL and TüV, and is the only double-sided power generation product in the world that has won three certifications.

Reliability advantage comparison

(1) Mechanical properties. The back side of the PERC double-sided process requires laser grooving, which weakens its own mechanical properties, increases the probability of cracks and debris during the application of the power station, and seriously affects the reliability of the solar modules; while the N-type solar cell is not used in the current technology. To the laser and other processes, it will not cause additional damage to the silicon wafer, and the silver paste is applied on both sides to improve the stability of the solar cell.

(2) Reliability in special environments. The N-type double-sided has passed the anti-PID test which is 6 times stricter than the conventional IEC standard test and the damp heat aging test which is 4 times stricter than the conventional IEC standard test. In the anti-PID, anti-humidity performance, has a strong ability. In addition, self-cleaning characteristics are also the advantage of attracting N-type double-sided technology investors. Especially in the high snow area, when the conventional solar modules stop generating electricity due to snow cover, the back of the PANDA BIFACIAL module uses snow reflected light to generate electricity, and the heat generated by the power accelerates the front snow melting rate, and the integrated power generation is higher. The following picture shows the Yingli self-built experimental power station. After the heavy snowfall, the N-type double-sided and conventional polycrystalline solar modules are compared with the self-melting snow, without any manual treatment.

How does the N-type turn against the wind and give birth to the sun?

Although the N-type double-sided has more material and performance advantages than the PERC double-sided, the current mainstream market is still the PERC technology, which is ultimately due to the price advantage brought by the lower cost of the PERC. It is understood that the PERC double-sided assembly only needs to increase the deposition back passivation layer and the back laser grooving process based on the existing production line, with almost no additional cost. Therefore, how to achieve effective cost reduction for N-type double-sided technology in the future will become the key to enhancing market competitiveness and competing for market share.

Yu Bo, deputy general manager of Yingli Green Energy, said that the N-type double-sided reduction can be started from two aspects. On the one hand, the high cost of N-type silicon wafers is one of the main reasons for the high cost of N-type double-sided, but in fact there is no difference in the production cost of N-type silicon wafers and P-type silicon wafers, but the current market demand is less. The result is higher prices, so the scale effect is needed to achieve the cost reduction of the silicon wafer. This is only a matter of time; in addition, the silver paste is also a part of the higher cost of the N-type double-sided, and can be reduced by techniques such as multi-main grid. The amount of pulp consumed, thereby achieving a cost reduction.

On the other hand, from the perspective of the enterprise, it is necessary to reduce the cost of the N-type double-sided technology through the two paths of cost reduction and efficiency improvement, such as the improvement of the production process of the enterprise itself and the optimization of the process control, which can control the manufacturing cost to some extent. The introduction of new equipment, new technology superimposed to increase component power, etc. can indirectly reduce production costs.

Today, with PERC as the mainstream, companies are also evaluating the next generation of mainstream technology. At present, whether it is N-PERT or HIT, or TOPCon, N-type double-sided is already the next generation of mainstream technology. Candidate. The proportion of N-type products in the third batch of front-runners has not been greatly improved. If the actual application cases can be successful in the front-runners, or the market share of N-type products will be promoted, accelerate its development to a more mature stage.

WSL Solar produces solar panels in a variety of sizes, shapes and outputs according to customer's specific requirements. We focus on high efficiency customized solar panels, small solar panels, OEM solar panels, round solar panels, small Sunpower solar panels, ETFE solar panels, marine solar panels, flexible solar panels and indoor solar cells.

Our main PV modules includes: 5V solar panel, 6V solar panel, 9V solar panel etc.

For more details, please visit https://www.wsl-solar.com/