WSL Solar Co., Ltd.

1.1.1 The role of the backsheet for custom solar panel

The back sheet is used for the rear surface of the custom solar panel and is one of the main encapsulation materials. A key feature of the back of a custom solar panel is that it must have very low thermal resistance and must be protected from water or water vapor, protect and support the solar cell, and have reliable insulation, water and aging resistance. Generally, it has a three-layer structure, an outer protective layer which has good environmental corrosion resistance, an intermediate layer which has good insulating properties, and an inner layer and EVA which have good adhesive properties. The back sheet is a very important component of solar PV modules that protects custom solar panels from harsh environments and ensures component life.

1.1.2 PV module requirements for back sheet materials

As shown in Figure 5-4, the backing material should be a composite material with more than 2 layers. The inner layer mainly provides mechanical strength and electrical insulation strength. The outer layer should provide weathering protection and water and gas isolation. Among them, the main component of a single film material and the UL flame retardant grade adhesive should be better than HB; in the composite layer of the film, the main component of the single layer film material and the cross-linking UL RTI (relative heat resistance index) value should be Above 105 ° C; the rebound material should meet the regulatory requirements for the control of harmful elements; a valid certificate must be provided;

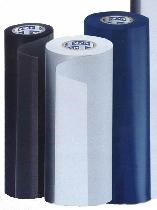

Figure 5-4 Back sheet film

1.1.3 Backsheet material analysis

Commonly used solar cell backsheets can be divided into TPT, TPE, all PET and PET / polyolefin structures. Wherein T refers to a polyvinyl fluoride (PVF) film of DuPont, USA, under the trade name Tedlar. P means a biaxially stretched polyethylene terephthalate film, that is, a PET film, which is also called a polyester film or a polyester film. E represents ethylene-vinyl acetate resin EVA. Polyolefin refers to various plastics with a carbon-carbon structure as the main chain. The solar cell backsheet is bonded between each of the indicated structural layers using a suitable adhesive.

1.1.4 TPT Backsheet

TPT (polyvinyl fluoride composite film) is used as a back protective encapsulation material on the back of the custom solar panel. The thickness is 0.17mm, the longitudinal shrinkage is not more than 1.5%, and the TPT used for encapsulation should have at least three layers: the outer protective layer PVF has good environmental corrosion resistance, the middle layer is polyester film, has good insulation performance, inner layer PVF requires surface treatment and EVA has good bonding properties. Tedlar used for encapsulation must be kept clean and free from dust or moisture. In particular, the inner layer must not be in direct contact with the fingers to avoid affecting the adhesion strength of the EVA. The TPT backsheet is made of PVF (polyvinyl fluoride film)-PET (polyester film)-PVF three-layer film backing film, referred to as TPT for short; TPT has a three-layer structure: the outer protective layer PVF has good environmental corrosion resistance. The middle layer is a polyester film with good insulation properties, and the PVF inner layer has good adhesion to surface treatment and EVA. The TPT must be kept clean and free of dirt or moisture, especially if the inner layer is not in direct contact with the fingers to avoid affecting the adhesion to the EVA.

The back cover of the solar cell - the fluoroplastic film is white, reflecting sunlight, so the efficiency of the component is slightly improved, and because of its high infrared emissivity, it can also lower the operating temperature of the component, and is also beneficial to improve the efficiency of the component. Of course, the fluoroplastic film first has the basic requirements for aging resistance, corrosion resistance and air resistance required for solar cell packaging materials.

TPT backsheets have good weatherability, excellent mechanical properties, ductility, aging resistance, corrosion resistance, air resistance, and resistance to various chemicals, solvents and colorants. Excellent anti-aging properties to maintain toughness and flexibility over a wide temperature range.

The white TPT reflects sunlight and increases the energy absorption rate of the component. Therefore, the efficiency of the component is slightly increased, and due to its high infrared emissivity, the operating temperature of the component can also be lowered, and the efficiency of the component is also improved. Enhance the water resistance of the components. It has a good sealing protection on the back of the component, which prolongs the service life of the component and improves the insulation performance of the component.

The TPT backing film should be protected from light, heat and moisture and stacked. Best storage conditions.

*********************************************************************************************************************************

WSL Solar produces solar panels in a variety of sizes, shapes and outputs according to customer's specific requirements. We focus on high efficiency customized solar panels, small solar panels, OEM solar panels, round solar panels, small Sunpower solar panels, ETFE solar panels, marine solar panels, flexible solar panels and indoor solar cells.

Our main PV modules includes: 5V solar panel, 6V solar panel, 9V solar panel etc.

For more details, please visit https://www.wsl-solar.com/