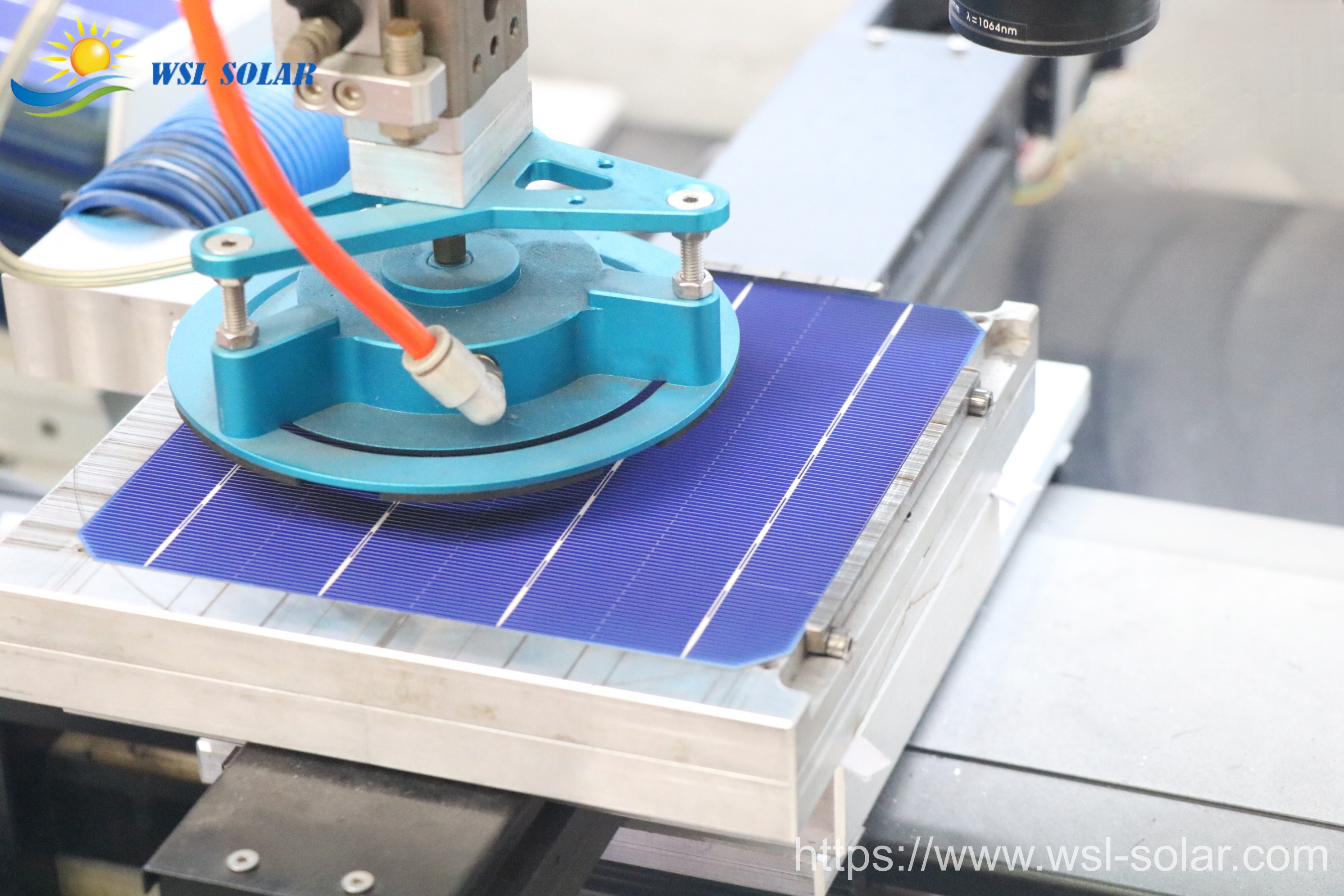

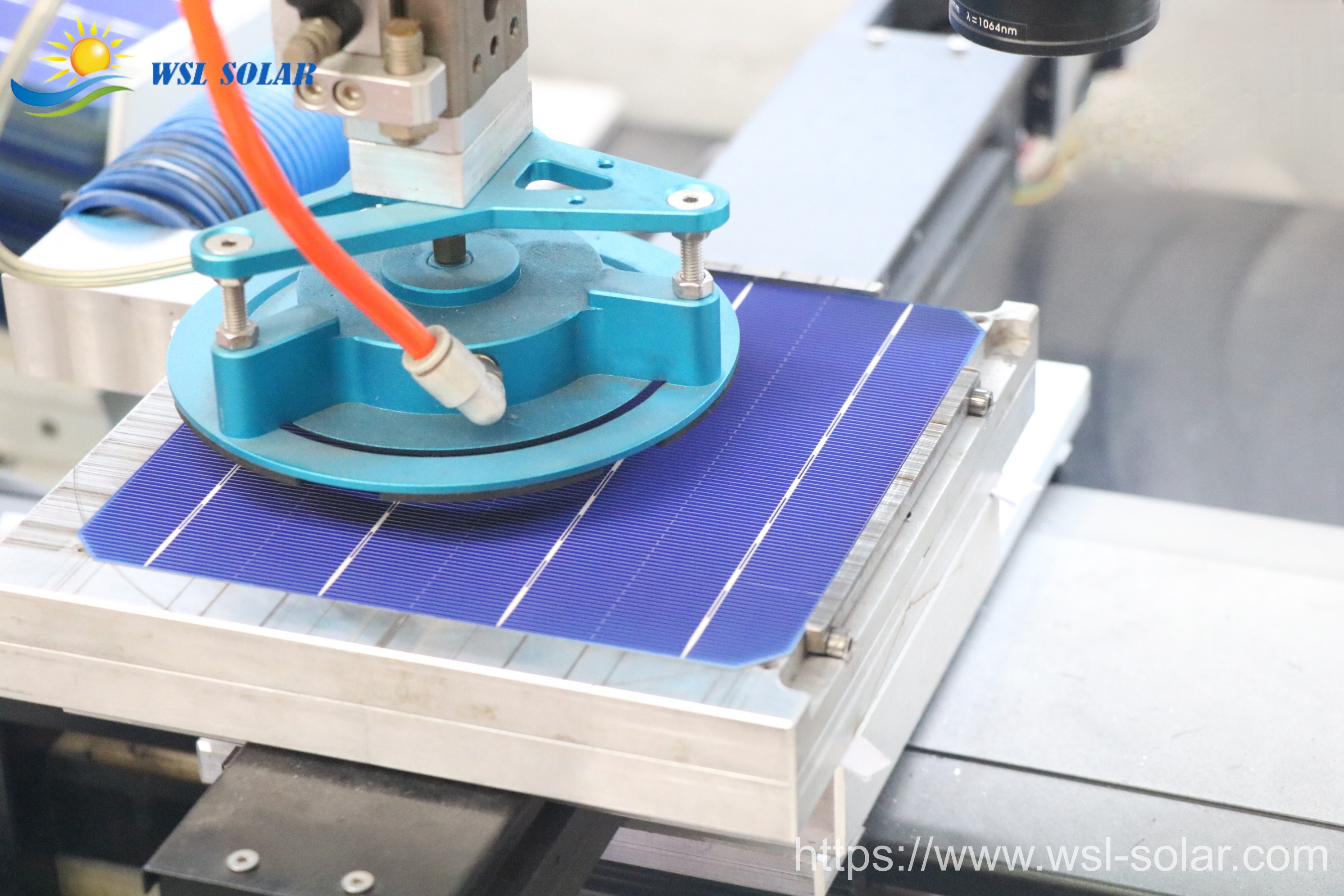

How laser cutting machine works to cut solar cells into small pieces according to your solar panel design?

Cutting solar cells into small pieces is a critical process in solar panel manufacturing, especially for high-efficiency custom solar panels with specific designs. Here’s a detailed breakdown of how laser cutting works for solar cells.

The Core Principle: Controlled-Fracture Cleaving (for Monocrystalline Cells)

The most common method doesn't "burn" through the silicon like a traditional laser cutter might with metal. Instead, it uses a highly focused, low-power laser to create a controlled thermal stress that induces a perfectly clean split along the crystal lattice. This is known as

"laser scribing and cleaving" or

"laser thermal separation."

Step-by-Step Process

1. Design & Programming

Step-by-Step Process

1. Design & Programming

-

Your solar panel design is translated into a cutting path by CAD/CAM software.

-

The software accounts for the wafer's thickness, material properties, and the required edge quality to minimize electrical losses.

2. Laser Scribing (The Key Step)

-

A short-pulse, low-power infrared (IR) laser is focused to an extremely fine spot on the surface of the silicon wafer.

-

The laser rapidly heats a tiny, localized volume of silicon (to over 1000°C) along the desired cut line.

-

This creates micro-cracks or modifies the material structure along a precise, shallow path (the "scribe line"). The depth is carefully controlled - typically only 10-30% of the wafer's thickness.

-

Crucially, the laser does NOT vaporize the material. It creates internal stress and a weakened zone.

3. Cleaving / Breaking

-

After scribing, a mechanical breaking step is often used.

-

A controlled bending force applies pressure along the scribe line.

-

Due to the induced stress and the guided micro-cracks, the silicon wafer fractures perfectly along the laser-defined path, following its crystalline structure.

-

This results in a clean, smooth edge with minimal micro-cracks and no thermal damage zone (HAZ) that would reduce cell efficiency.

Why Laser Cutting is Superior for Solar Cells (Compared to Mechanical Saws)

|

Feature |

Laser Scribing & Cleaving |

Mechanical Diamond Saw/Scribing |

|

Material Loss (Kerf) |

Minimal (only the laser scribe line). Saves expensive silicon. |

Significant (the width of the diamond blade). Wastes material. |

|

Edge Quality |

Very clean, smooth, low micro-crack depth. Higher mechanical strength. |

Rougher, more micro-cracks, weaker edges prone to chipping. |

|

Precision & Flexibility |

Extremely high. Can cut complex shapes, curves, and very small shingles easily. |

Low flexibility, typically only straight lines. |

|

Throughput & Speed |

Very high speed (meters per second). Non-contact process. |

Slower, mechanical wear on blades. |

|

Dust & Contamination |

Almost none for the scribing step. Clean process. |

Generates silicon slurry/dust that must be cleaned, causing contamination. |

|

Thin Wafer Handling |

Excellent. The only viable method for wafers <150μm thick without breakage. |

High breakage rates on very thin wafers. |

Critical Requirements for the Laser Process

-

Ultra-Precision: Cutting must be accurate to within microns to ensure cells are identical for automated stringing.

-

-

Minimal Heat Affected Zone (HAZ): The laser must not overheat the silicon, as heat creates defects that trap electrons, killing cell efficiency.

-

-

Strength Preservation: The cut edge must remain strong to survive the subsequent manufacturing processes (transport, stringing, lamination).

-

Summary

In essence, a solar cell laser cutting machine uses a

low-power, focused laser to "guide" a fracture through the crystalline silicon, rather than melting its way through. This

cold-cutting process maximizes material yield, preserves the electrical quality of the silicon, and enables the intricate cell designs needed for today's high-efficiency, high-power solar panels. It is an enabling technology for the continuous improvement in solar panel performance and cost-effectiveness.

Posted by Carrie Wong / WSL Solar

WSL Solar has been a quality and professional manufacturer of custom solar panels, solar mini panels, IoT solar panels and solar solution provider in China since 2006.

https://www.wsl-solar.com